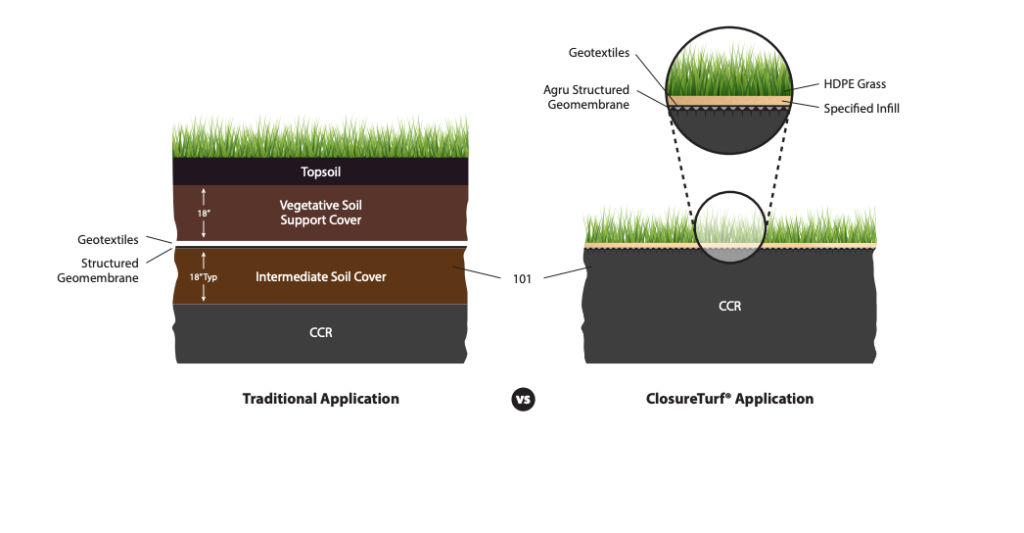

Traditional Closure Design vs. Geosynthetic Closure

Prescriptive final cover designs for landfills have historically included a compacted soil liner, geomembrane liner, a drainage layer, and a vegetative soil cover. These traditional capping options involve large volumes of soil that many coal-fueled plants may not have available

Because of challenges associated with prescriptive designs, and specifically the unique requirements for coal combustion residual (CCR) surface impoundments and landfills, ClosureTurf was created as an alternative Subtitle D capping option and now has a decade of installed performance. In addition to eliminating the need for the intermediate soil cover and vegetative layer, these turf systems have many advantages over their traditional counterparts, including faster installation times, safer construction methods, improved storm water quality, and significantly reduced maintenance and post-closure costs. For surface impoundments, using an alternative capping design can also greatly reduce the amount of disturbance of the existing CCR material within the impoundment.

ClosureTurf includes a three-component system comprising a structured geomembrane, an engineered turf, and a specified infill. The structured geomembrane provides both drainage and high interface friction for stability. It serves as the barrier layer to minimize infiltration through the cover system into the CCR. The engineered turf is made of synthetic grass blades tufted into two layers of geotextile backing. It is the protective layer that covers and protects the underlying geomembrane from ultraviolet (UV) degradation and wind uplift. The specified infill provides additional UV protection and allows the system to withstand traffic loads.

Soil Construction Factors

Eliminating the need for a two-foot soil and vegetative cover layer improves safety while reducing the carbon footprint of the closure, as there is no need to transport soil to the site.

A comparison of a traditional vegetated system and geosynthetic

turf system demonstrates the two-foot elimination of soil.

This means the removal of thousands of trucks from local roads, as ClosureTurf eliminates the need for approximately 550 truck trips (275 round trips) per acre that would otherwise be needed to transport soil to and from a borrow site. Less equipment also means reducing the carbon footprint of the closure by approximately 80 percent compared to traditional soil/vegetative covers. The reduction in size, number, and duration of equipment further contributes to an overall increase in safety on both the project site and local roads, as well as the reduction of dust at the site, mud on the roads, and noise impacts to the surrounding community. Most traditional closures also require destruction of land for project soil sources, resulting in additional environmental impact and loss of future land use.

ClosureTurf installs two to three times faster than a traditional soil cover and uses fewer and lighter pieces of equipment. The increase in project-completion efficiency means that owners, operators, and their design and construction teams can effectively cover more acreage per day. Additionally, the standardization of engineering and construction details associated with engineered turf systems reduces the burden on the regulatory review and approval process. The use of this system also makes it easy to install in smaller, incremental closures. The sooner full cells can be capped, the sooner leachate is reduced, providing significant savings for the owner.

Geosynthetics are lighter and improve the stability of CCR closures by eliminating the weight of the traditional soil and vegetative cover. This reduces the static load surcharge on the impoundment or landfill and the dewatering needed to stabilize a CCR impoundment for final closure, which in turn can shorten the construction schedule. In the event that future access to the ash is needed, the geosynthetic system can be easily cut and resealed back together. A vegetated soil cap, in this instance, would require excavation, management of sediment runoff, and then complete reconstruction.

Learn more about Geosynthetic Solutions for Final Closure of Coal Combustion Residuals: